A manufacturer of cryogenic cooling systems was confronted with a demand for bigger, more efficient systems. One specific customer wanted a centrifugal pump to transport helium gas at a temperature of -193 degrees Celsius. Simply enlarging a small pump did not deliver the required result, and experimental optimisation by using prototypes is a time-consuming, costly process. Where to go from here?

Calculating a complete CAD-design is often too complex and time-consuming. Sioux’s CFD analysts quickly managed to determine the critical elements of the design and to calculate and optimise those separately. However, Mathware was able to take the client one step further. Due to our extensive experience with similar problems, Sioux was able to suggest and quantify new improvements for the design.

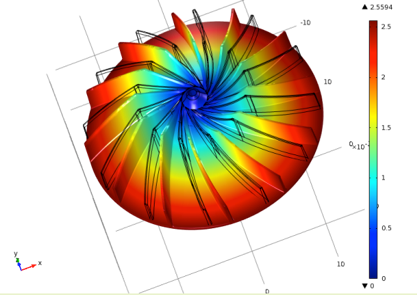

Sioux helped the client by supporting the design process through virtual prototyping and computer simulations. This way, the client could meet the customer’s needs exactly: increased capacity combined with a high output.

Multi-Physics, Cryogenic fluid dynamics, Turbulence, Algorithm development, Moving meshes and Form optimisation. Mathware technologies: openFOAM, Python and in-house developed fluid structure interaction solvers.