In machines that produce micro-electronic wafers (which are a component of semiconductor materials such as integrated circuits, transistors and diodes), internal temperatures increase considerably during the production process. This leads to a decrease in product quality. A complex and lengthy journey to adapt the hardware would potentially have led to a solution, but Sioux approached the issue from a different perspective.

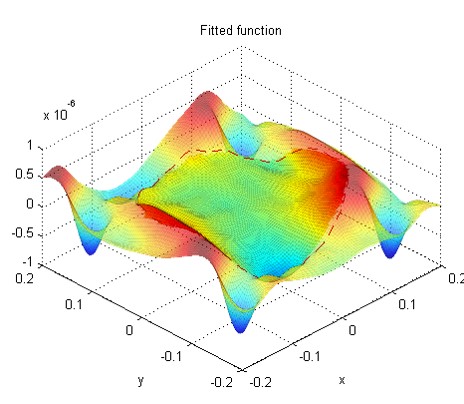

With our knowledge of mathematics and multiphysics, Sioux created insight into the dynamic thermal effects. Based on this insight, Sioux developed a model that calculates how the machine should be fine-tuned within 12 milliseconds. This way, deviations in products as a result of temperature increases in the machine during production are continually corrected.

Thanks to this method, the wafer machine’s accuracy rate is now twice as high, and its throughput speed was increased as well. The results were so positive that the client applied for a patent for this Mathware.

Multi-physics, Thermal dynamics, Approximation theory, Modal analysis, Non-linear optimization, Scientific computing. Mathware technologies: Comsol, Ansys, Python, openFOAM, ICEM CFB.